Ryan Howell

Nov 25, 2025

Elliott Round

Aug 2, 2023

Metallic materials, due to their conductive nature, interact with light in a way that significantly differs from dielectric (non-metallic) substances. This distinctive interaction poses a unique challenge in texture scanning, particularly when attempting to capture materials that comprise both metallic and non-metallic elements using the same system. Due to these complexities, most metal assets found in asset libraries are typically not scanned. Instead, they're often a composite of scanned materials from other sources, layered with digital imperfections to emulate a metal-like appearance.

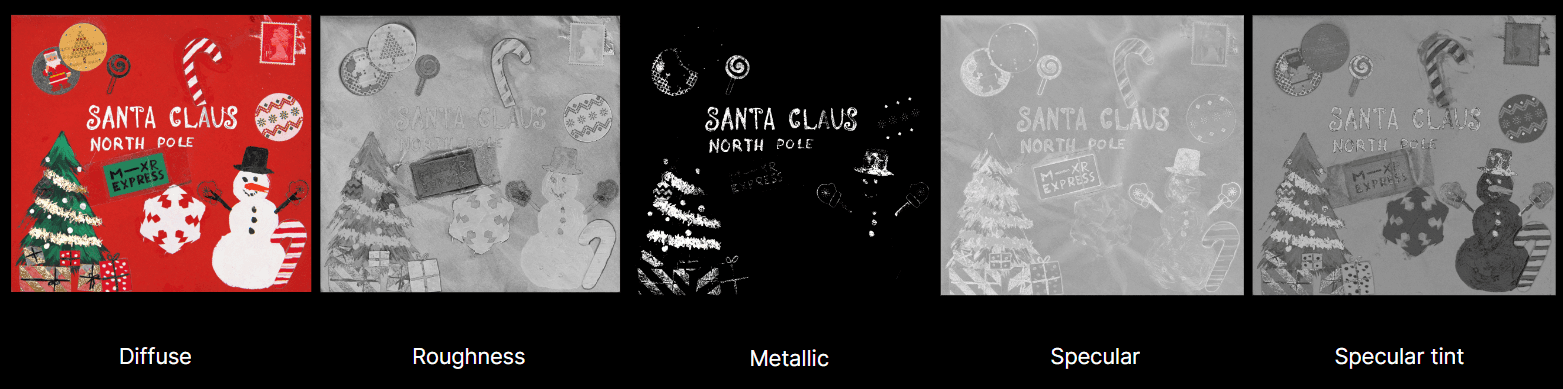

To date, M-XR’s scanning technology has effortlessly handled the acquisition of ‘conventional’ PBR (Physically Based Rendering) materials. A core pillar of M-XR's technology has always been scalability – not just in terms of capture and delivery, but also extending to novel material properties. Testament to this scalable technology, we have now broadened our capabilities to include Metallic and Specular-tint maps.

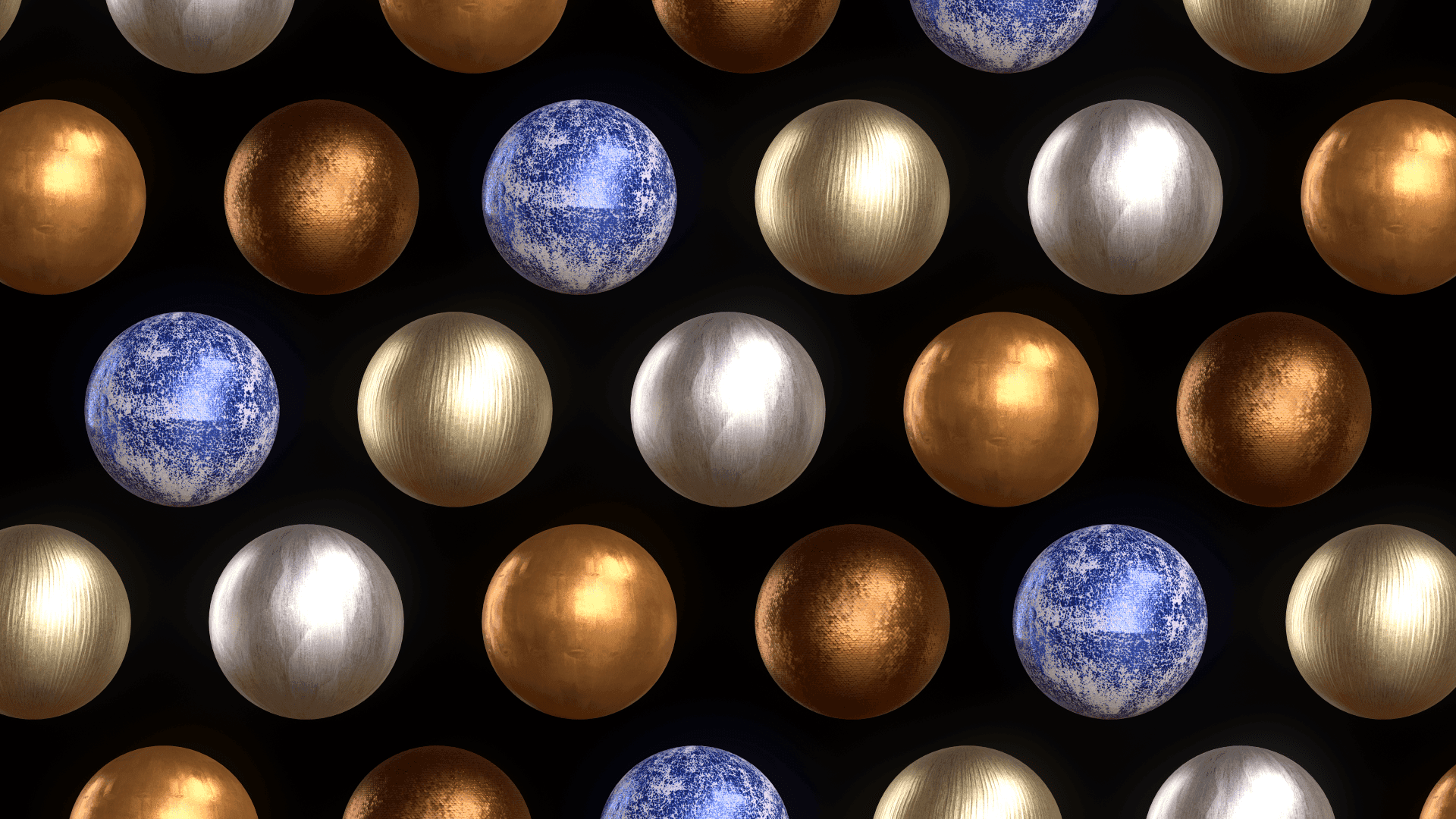

The below renders (blender) makes it easy to understand the power of this new feature. By capturing a swatch composed entirely of metal, we offer a glimpse into the potential of a scanning system solely dedicated to metallic textures. The image exemplifies how accurately our scanner can reproduce the unique lustre and sheen of metal surfaces.

We deliver material properties at a per-pixel basis, allowing us to capture complex composite materials containing both Metallic & Non-Metallic properties as demonstrated with this fabric below.

The inclusion of these supplementary maps in our scanning repertoire has been a pleasing step forward. As we continue M-XR’s technological journey, we remain committed to adding more map outputs and broadening the scope of our capabilities. This new milestone in metallic texture scanning signifies our dedication to offering the most advanced, scalable texture scanning solutions in the industry.